All Step Drill Bits have Split Points and come in two different materials.

· The Split Point reduces “Walking” which is the tendency of a spinning bit to rotate away from the point at which you want to drill.

· Because CBN(cubical boron nitride)is a much harder abrasive than even silicon carbide or corundum, a better an sharper cutting edge is

achieved without burrs.

· Because of this higher dimensional precision,the drill bits will last considerably longer while maintaining precise process tolerances.

· The High Speed Steel(HSS) allows the bit to cut faster than High Carbon Steel. At room temperature,HSS and high carbon steel have an

equivalent hardness;at elevated temperatures HSS become advantageous.

· Reduces set up time

· No more CBN-ground flutes without burrs mean a superior cutting edge an longer tool life.

· Each step has a radially adjusted relief produced by CBN grinding,relating directly to the diameter of the step, so the cutting edge is always the highest point of the diameter

· Each step is axially CBN relief-ground, meaning the cutting edge is also the highest point of the axial cutting axis

· The cutting edge of each step has relief angle,meaning the cutting edge is also the highest point in advance direction

Use Steel drills for :

· Sheet metal working in electrical, sanitary engineering, heating technologies, automotive, mechanical engineering,switching systems and aviation

· Non-ferrous metal,steel,stainless steel,thermoplastics, duroplastics ,sheet metals up to 0.16”(8 ga.)thick

· Center,spot-drill,bore and debur - all in one operation

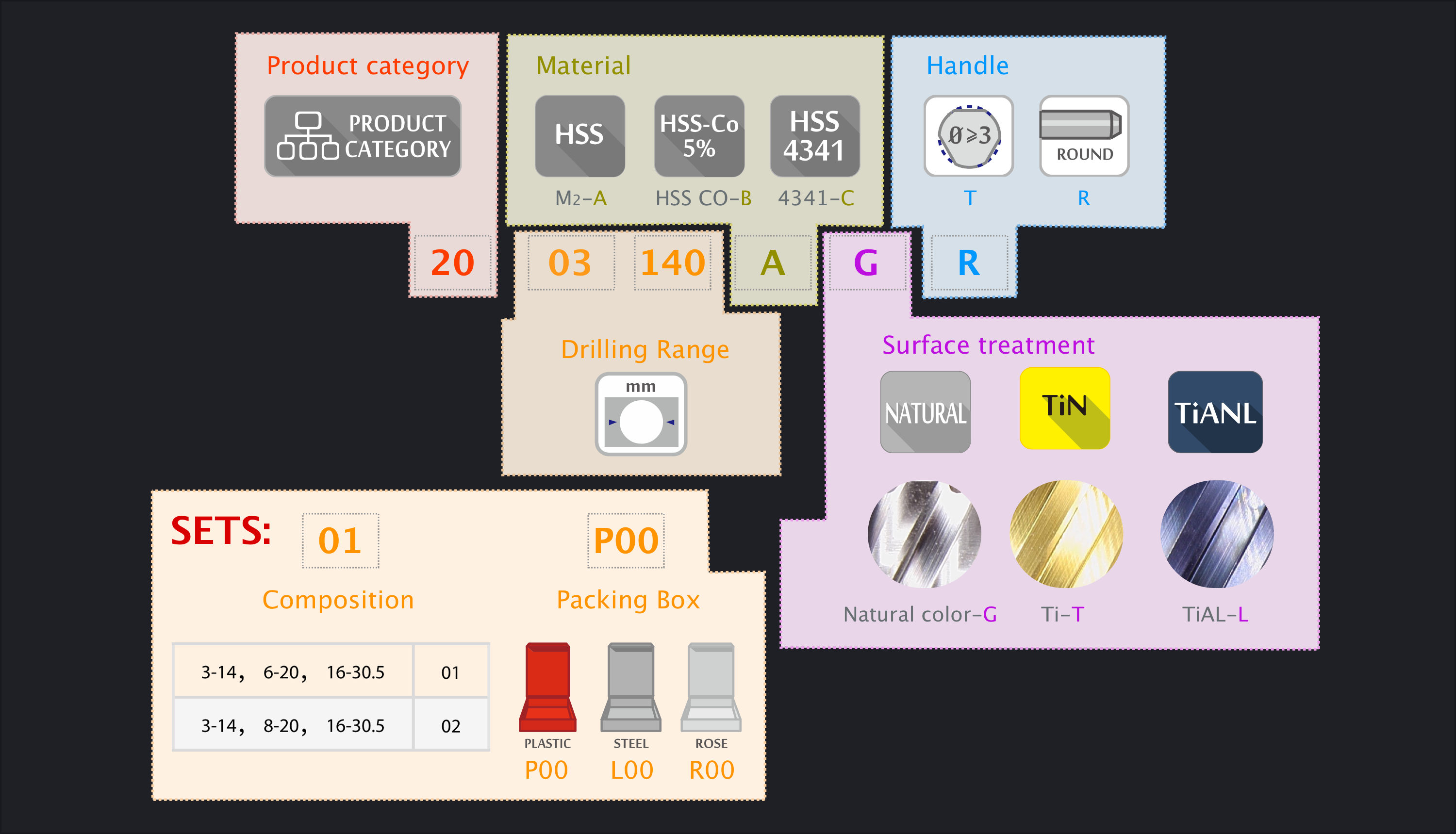

| TIN |

· For hard materials · Extended service lives · Higher cutting speed · Higher tool life

|

· Temperature resistance up to 600 ° C · Surface treatment ca. 2.500 HV · Layer Thickness up to 2 μm · Reduces cold weldings

|

| TiAIN |

· For particularly hard materials · Outstanding service lives · Highest cutting speeds · Optimized tool life

|

· Surface treatment ca. 3.500 HV · Layer Thickness up to 4 μm · Reduces cold weldings · Temperature resistant up to 800°C, cooling not necessary

|

· Sheet metal working in electrical, sanitary engineering, heating technologies, automotive, mechanical engineering,

switching systems and aviation

· Non-ferrous metal, steel, stainless steel, thermoplastics ,duroplastics, sheet metals up to 0.16”(8 ga.) thick

· Center,spot-drill, bore and deburr-all in one operation